Suspension Bushings: Urethane vs Rubber

The suspension on our car needs to handle a lot of loads. As we corner the forces are transferred through the body to the tires via the suspension. This adds up to thousands of pounds of force in which the frame, a-arm, and spindle or axel must transfer. In the process, it all must travel through the lowly suspension bushing, a part which you may have given little thought or attention. We will address suspension bushings and show you why it is essential to understand its purpose & environment and some options to help improve how your car handles and responds.

Most muscle cars and classics have rubber suspension bushings at the point where the a-arms attach to the uprights or frame. When these rubber bushings became available in the ’50s they were seen as a significant improvement over the metal of their metal predecessors which required lubrication and suffered wear as the suspension moved. Rubber was maintenance free – no greasing – and they offered isolation from road vibration and most important; they were CHEAP. Automakers could not resist and most suspensions from that time forward have rubber bushings.

All of the benefits mentioned would be great if you never cornered your car. I don’t know about you but I like cornering my car. Once we rack it into a turn the load on the bushing dramatically increases. Remember, these bushings are rubber, and rubber flexes compress, stretches and in doing so changes the suspension alignment which can do bad things to handling. The images below show a drawing of a loaded and unloaded suspension bushing as would occur when your car enters a turn.

Shifting Camber

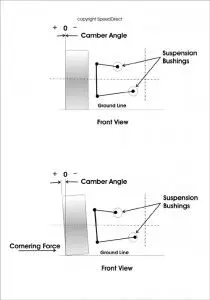

As you can see the whole center of the bushing moves to one side as it is loaded. This movement results in camber loss on the front suspension as you corner. Why do you care? Camber is the angle of the tire to the road. Ideally, you want the tire perpendicular to the road/track surface, this is where the tire can produce maximum grip or traction. If the camber angle changes to positive it means loss of traction in the turn.

The illustration of the camber angle shows how soft rubber bushings allow the suspension to dynamically change camber to the positive (bad) side which lifts the contact patch and reduces traction.

Steering by Bushing Deflection

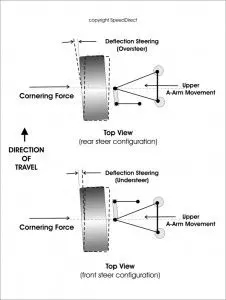

Another steering input in which squishy bushings can change steering angle as you enter a corner is deflection steering. This is a bad side effect of having a flexible bushing in the system. Deflection steering can take two forms; deflection oversteer or deflection understeer depending on how your car’s steering is designed. If the steering link in front of the axle (front steer) it can cause an understeer or the tendency to widen the radius of the intended steering path. The other condition occurs if the steering link is behind the front axle it can cause oversteer or the tendency to decrease the radius of the intended steering path. Either way, your car is not doing what you wish or expect as you take a corner.

What can be done?

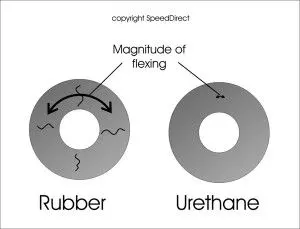

There are aftermarket urethane bushings which greatly reduce the deflection of the suspension caused by soft bushings. This is because they are extremely rigid, almost like metal, but do not have the disadvantage of metal to metal contact about wear. Like any solution, they have some drawbacks. Since they are so much stiffer than rubber they do not flex as a rubber bushing does. As you can see from the suspension motions in the drawings, the bushing is subject to flexing in multiple planes. In addition to this, there is also the applied torque of the a-arm as it rotates on the cross shaft causing the factory rubber bushing to flex by twisting. Urethane bushings flex only slightly, instead they slide on the cross shaft. Even if you grease them when you install them over time the bushing will start to bind. This binding is slightly detrimental to the free movement of the a-arm and usually results in annoying squeaks and squawks as the bushings dry out. Just keep a bottle of rubber lubricant or Armor All handy.

On the SpeedDirect upper a-arm alloy a-arm for C2-C3 Corvettes, we chose rigid composite bushings which are Teflon impregnated to eliminate all of the described problems of bushings. They are stiff, do not flex, they run smoothly on the cross shaft, and need no lubrication for the life of the installation.